Welcome to the NFS-320 Programming Manual‚ your guide to configuring and operating the NFS-320 fire alarm control panel. This manual provides essential information for installing‚ programming‚ and maintaining the system‚ ensuring compliance with safety standards and optimal performance.

System Architecture and Components

The NFS-320 system features a modular design with key hardware and software components. It includes the control panel‚ keypad‚ detectors‚ and communication interfaces‚ ensuring reliable fire alarm monitoring and control.

- Control Panel: Central unit managing all system operations.

- Keypad: For programming and system interaction.

- Detectors: Smoke‚ heat‚ and manual pull stations;

- Communication Interfaces: EIA-232 port for remote connectivity.

2.1 Hardware Components

The NFS-320 system consists of several key hardware components that work together to provide reliable fire alarm monitoring and control. These include:

- Control Panel: The central unit that processes signals and manages system operations.

- Keypad: Used for programming and interacting with the system‚ featuring essential control keys like Acknowledge and Scroll.

- Detectors: Includes smoke detectors‚ heat detectors‚ and manual pull stations to detect potential fires.

- Power Supplies: Essential for ensuring uninterrupted system operation during power outages.

- Communication Modules: Enable connectivity to remote terminals or computers via EIA-232 ports.

- Annunciators: Optional ACM Series annunciators for enhanced system monitoring.

Proper installation and wiring of these components are critical for system performance. The control panel must be mounted securely‚ and power-limited wiring should be separated from non-limited wiring to meet UL requirements. For detailed specifications‚ refer to the NFS-320 Installation Manual.

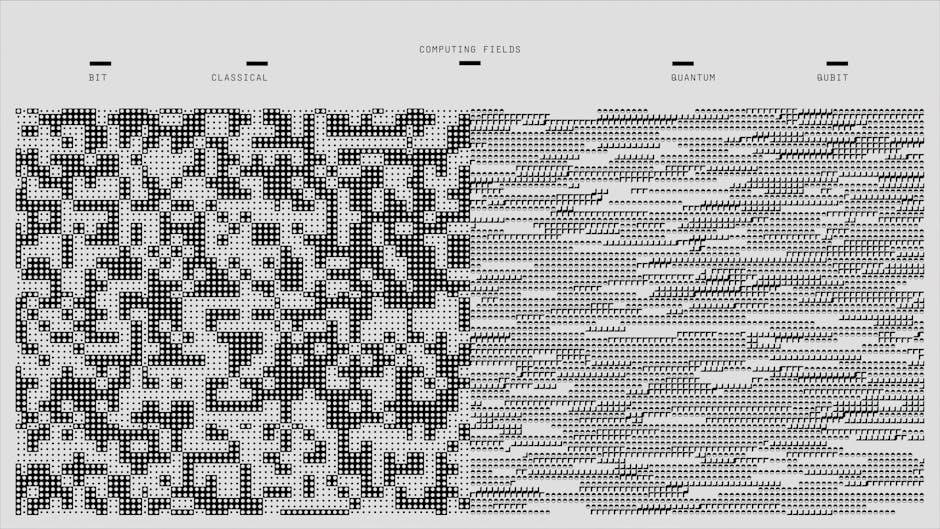

2.2 Software Architecture

The NFS-320 system operates on a robust software platform designed to handle advanced fire alarm and emergency communication functions. The software architecture is structured to support various system configurations‚ including standalone and networked setups. It enables features like programming through the keypad or VeriFire Tools‚ a PC-based programming interface. The system supports multiple protocols and can integrate with optional modules for enhanced functionality. Security is ensured through password-protected access‚ preventing unauthorized changes. Regular software updates are recommended to maintain peak performance and access new features. For detailed instructions on software operations‚ refer to the NFS-320 Programming Manual. The architecture ensures scalability‚ allowing the system to adapt to growing needs while maintaining reliability and ease of use. Proper software configuration is crucial for ensuring the system operates according to local fire safety regulations and standards.

Installation and Setup

Install the NFS-320 system by connecting batteries and ensuring all power sources are disconnected. Follow the manual for wiring and configuration. Use VeriFire Tools for programming and setup.

3.1 Installation Steps and Precautions

Begin by disconnecting all power sources to avoid electrical hazards. Carefully unpack and inventory all components. Mount the control panel securely‚ ensuring proper ventilation. Next‚ connect the batteries using the provided interconnect cables (P/N 75560 and 75561). Proceed to wire the system‚ adhering to UL requirements for power-limited and non-power-limited circuits. Refer to the NFS-320 Installation Manual for specific wiring diagrams and guidelines. After wiring‚ power on the system and perform a self-test to verify functionality. Use VeriFire Tools to program the control panel‚ ensuring all settings meet local fire safety codes. Finally‚ conduct a thorough system test‚ including smoke and heat detector sensitivity checks‚ to ensure reliable operation. Always follow manufacturer instructions to guarantee a safe and compliant installation.

3.2 Initial Configuration and Wiring

Start by connecting the control panel to the desired power source‚ ensuring all wiring meets local electrical codes. Carefully wire smoke and heat detectors‚ manual pull stations‚ and audible devices‚ following the layout specified in the NFS-320 Installation Manual. For networked systems‚ connect the EIA-232 port to a PC or remote terminal for monitoring and programming. Use VeriFire Tools to configure the system‚ setting up zones and ensuring proper communication between components. After wiring‚ perform a power-up self-test to verify all devices are recognized. Address any issues promptly to ensure system reliability. Proper configuration and wiring are critical for maintaining fire safety and compliance with regulations.

Programming the NFS-320 System

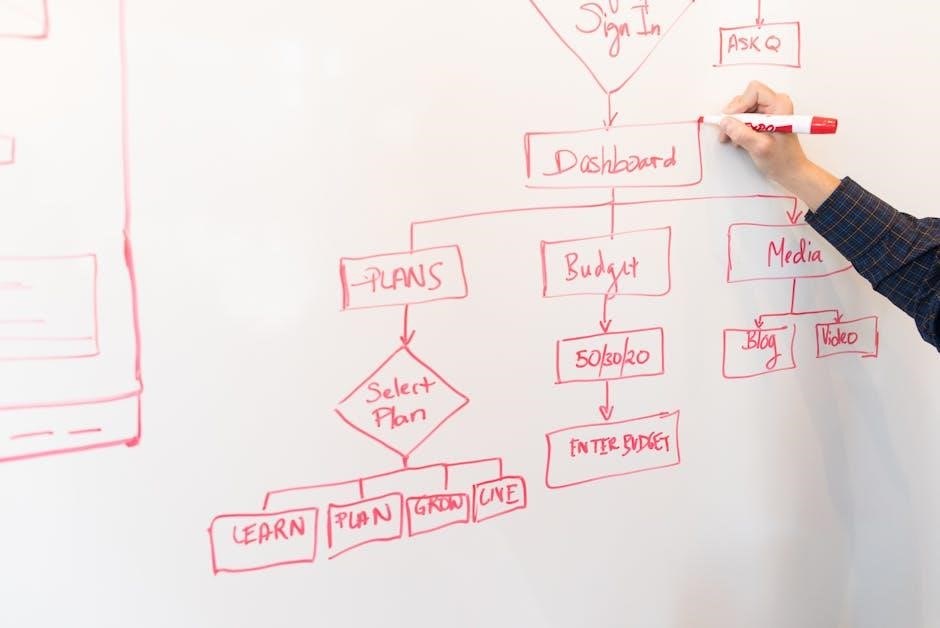

Program the NFS-320 using the keypad or VeriFire Tools for advanced functions. Define zones‚ set sensitivity levels‚ and configure special functions like Presignal and PAS. Ensure all settings are tested thoroughly for optimal performance.

4.1 Using the Keypad for Basic Programming

The NFS-320 keypad serves as the primary interface for basic programming tasks. Use it to navigate menus‚ define zones‚ and configure system settings. Start by entering the programming mode using the appropriate key sequence. Once access is granted‚ you can adjust zone settings‚ such as assigning zone types (e.g.‚ smoke‚ heat‚ or manual pull stations) and enabling or disabling specific features. The keypad also allows you to set sensitivity levels for detectors and configure time delays for functions like Presignal or Positive Alarm Sequence (PAS). For each change‚ ensure you follow the correct sequence of key presses to save the configuration. Testing each setting is crucial to confirm proper operation. While advanced features may require VeriFire Tools‚ the keypad provides efficient control for essential programming needs‚ ensuring your system operates as intended.

4.2 Advanced Programming Functions

Advanced programming functions on the NFS-320 enable customization beyond basic settings‚ allowing for tailored system behavior. These include configuring Special Zones‚ Releasing Functions‚ and network integration. Special Zones can be programmed to trigger specific responses‚ such as activating strobe lights or voice messages during alarms. Releasing Functions allow for controlled deactivation of systems‚ such as releasing clean agents or shutting down HVAC systems. For networked systems‚ advanced functions include syncing multiple panels and enabling remote monitoring. The keypad supports these configurations‚ but complex setups may require VeriFire Tools for precision. Additionally‚ advanced features like Presignal and Positive Alarm Sequence (PAS) can be fine-tuned to meet specific site requirements. Ensure all changes are thoroughly tested to maintain system reliability and compliance with safety standards. Always refer to the manual for detailed instructions to avoid errors during implementation.

Advanced Features and Customization

The NFS-320 offers advanced features like Special Zones‚ Releasing Functions‚ and network integration for tailored system behavior. Customization options include Presignal‚ Positive Alarm Sequence (PAS)‚ and remote monitoring capabilities.

5.1 Special Zones and Releasing Functions

Special Zones on the NFS-320 allow for customized alarm responses‚ enabling specific actions during an emergency. Releasing Functions‚ such as Clean Agent Release or Pre-Discharge Notification‚ can be programmed to trigger at defined stages. These features ensure tailored system behavior‚ enhancing safety and operational efficiency. The Presignal function delays alarm activation‚ allowing investigation before full alert‚ while Positive Alarm Sequence (PAS) requires confirmation from multiple detectors to reduce false alarms. Both functions are configurable via the keypad or VeriFire Tools software. Special Zones can also integrate with optional modules‚ such as the ACM Series annunciator‚ for expanded monitoring. Proper setup ensures compliance with safety standards and system reliability. Advanced customization options empower users to adapt the NFS-320 to unique facility needs‚ making it a versatile solution for fire safety and security applications.

Maintenance and Troubleshooting

Regular maintenance is crucial for ensuring the NFS-320 system operates reliably. This includes inspecting detectors‚ cleaning components‚ and testing alarm functionality. Refer to the manual for detailed schedules and procedures. Troubleshooting involves identifying and resolving issues like false alarms or communication errors. Use diagnostic tools to isolate faults and address them promptly. Always disconnect power before servicing to avoid risks. The system’s event log provides insights into historical issues‚ aiding in proactive maintenance. For complex problems‚ consult the troubleshooting guide or contact technical support. Proper upkeep ensures the system remains effective‚ safeguarding people and property. Regular software updates and compliance with safety standards are also essential for optimal performance and reliability.